- Energy-efficient

- Total integration

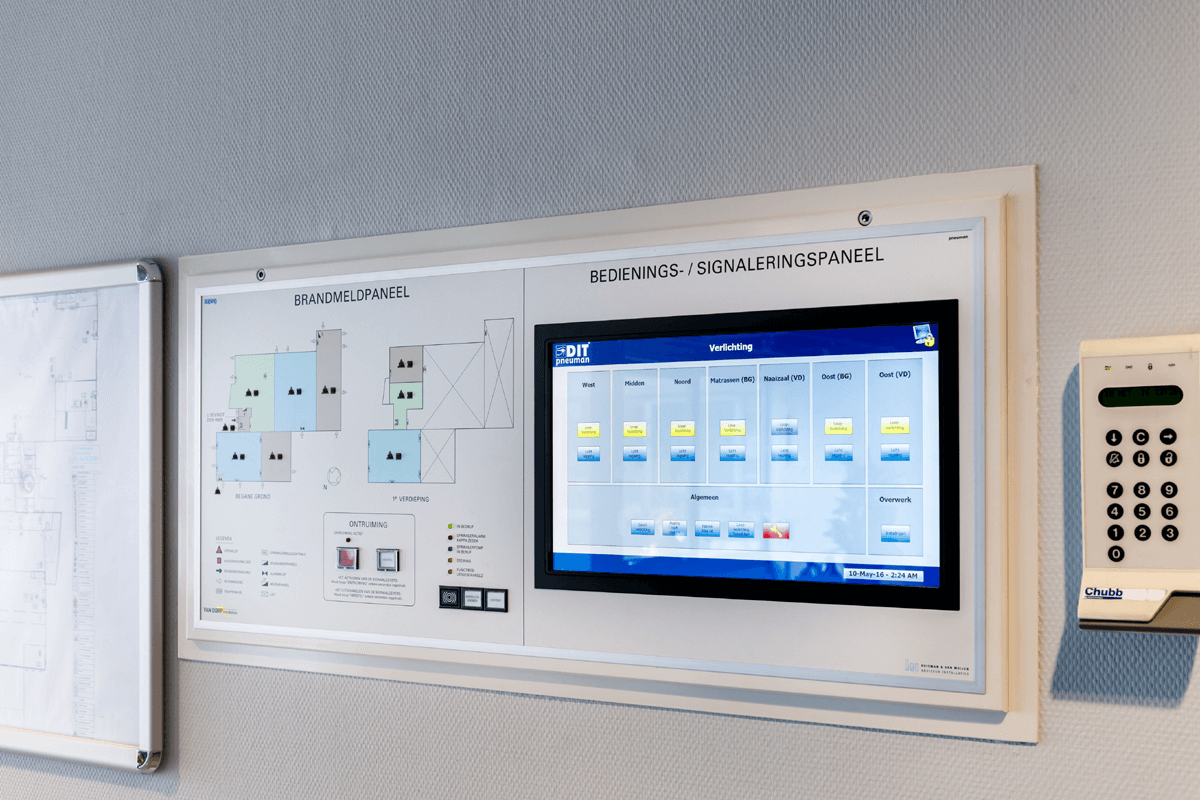

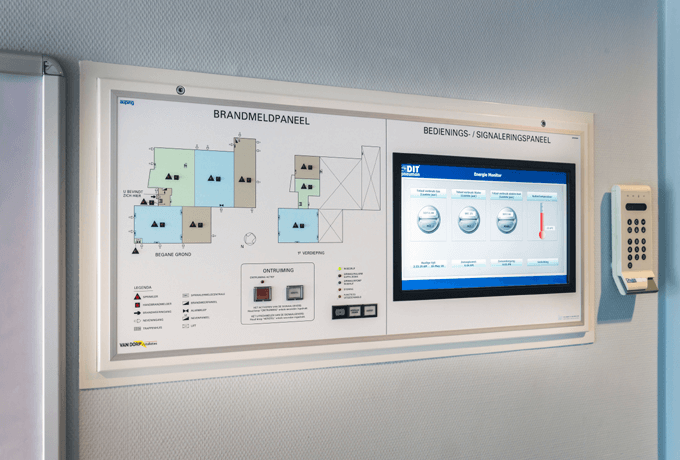

- Central and local operation

All-in-one system

Total integration at Auping. All aspects of the massive installation are connected through our operating system. It does not get much more efficient than this. A central control panel, local control panels and monitors allow users to switch, monitor or manage from multiple locations and at all levels.

General lighting

Motion sensors and a light sensor on the roof automatically control the general lighting system, unless that is not needed. For excursions, for example, the motion sensors are overridden by entering a code on the touchscreen.

Emergency lighting

Clever use was made of emergency lighting. If needed, the emergency lighting can be used as an additional light source or as security lights. Naturally, the emergency lighting system meets all requirements and is being excellently safeguarded.

Local lighting

Local lighting can be controlled by the operators for each part of the factory. It is also possible to have the lighting switch automatically. Eight control panels are connected to the main switch, i.e. the server.

Energy

Lighting and heat are not the only systems that cost energy. The manufacturing process of matrasses and beds requires quite a lot of energy as well. Auping does everything to conserve as much energy as possible. They generate their own electricity with solar panels and use a pellet stove.

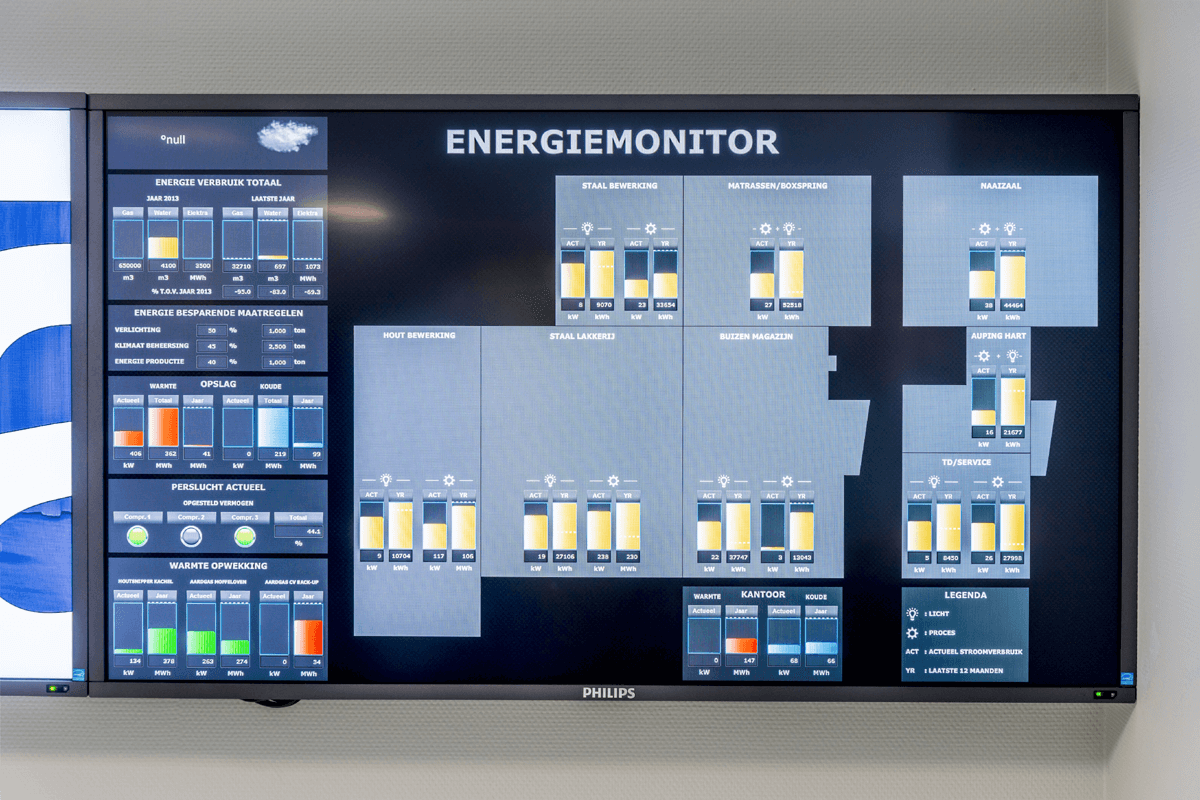

Monitor

To make all employees and visitors aware of the energy being used, the central hall features a simple energy monitor next to the fire alarm annunciator. It displays the current use of gas, water and electricity.

Energy management

All energy streams can be viewed and stored online. The saved date provides input with which to optimise the company’s energy policy. A large monitor displays the daily, weekly and annual energy consumption of all processes. It also shows how the actual use relates to the prognosis and the data from previous years.